PET Hot Fill PET Moderate Temperature Fill Hot Fill Temperature Comes to 92ºC Output 16000 BPH (500ml)

PET MIneral Water Bottle PET CSD Bottle PET Asepsis Fill Output 24000 BPH (500ml)

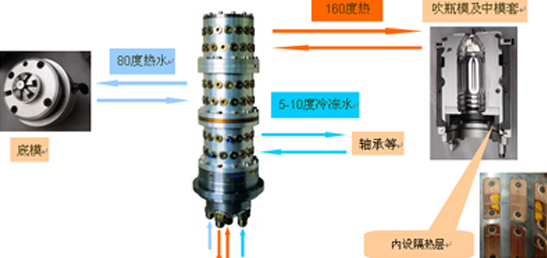

PF uploading system position designed as per customer's site requirement Adopt corner preform sending guiding rail which saved spaced

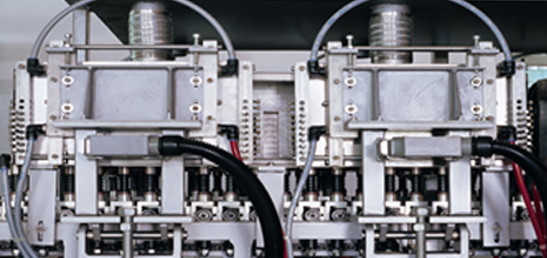

First invented rotary preform infeeding structure in China, which is very stable and reliable and applicable of different size of preform.

The servo conveying system with high accuracy of position,quick speed and good stability, as there is no air resource which is energe saving and with low maintenance charge.